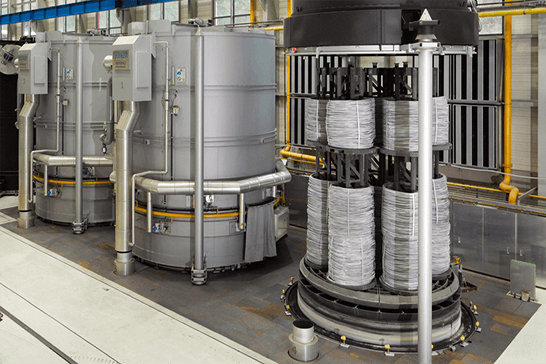

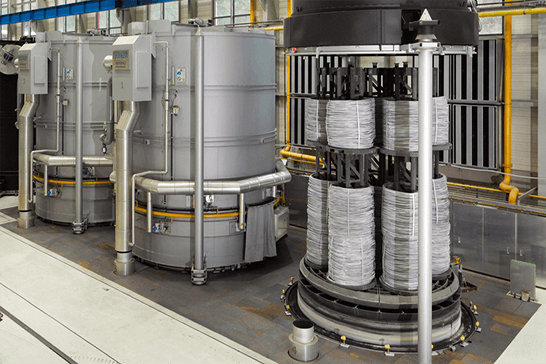

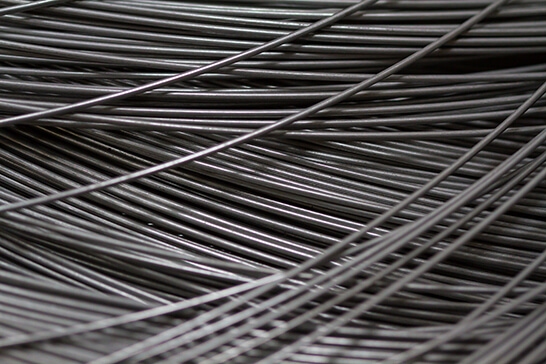

上海睿雄实业集团是中国专注于冷镦优质钢丝的标杆企业。整个管理团队拥有20年的行业经验。我们与许多汽车行业的一级供应商建立了良好的关系,所有线材均来自品牌钢厂。所有订单都100% 可追踪。

交货条件

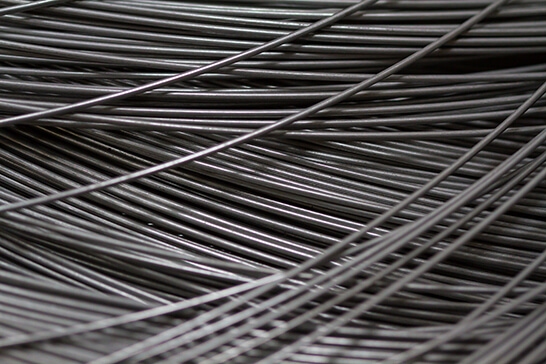

表面质量

- : 连续平滑

- : 无接缝、重叠、凹坑、划痕和绘图疤痕

- : 无锈

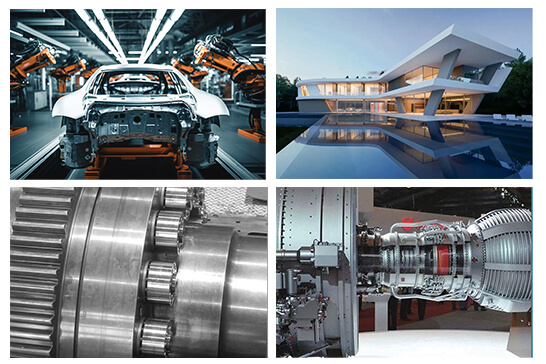

应用程序

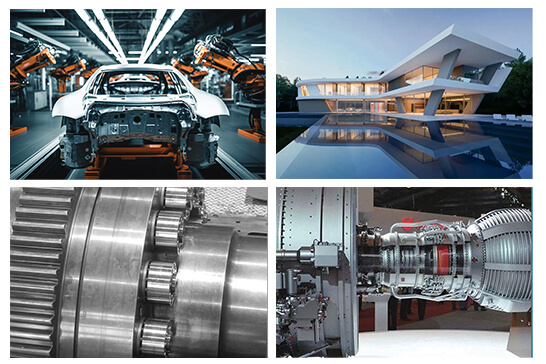

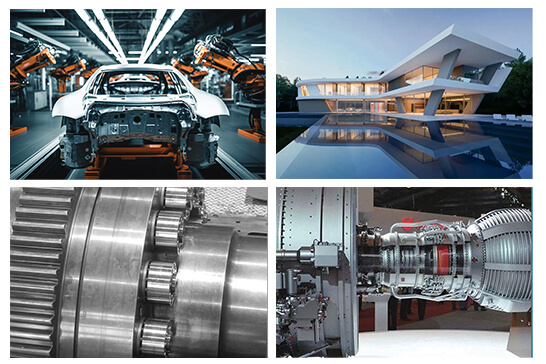

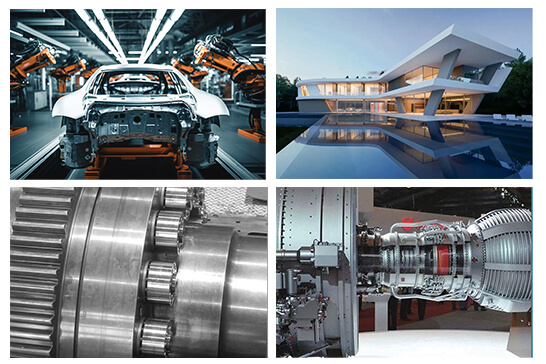

- : 汽车工业

- : 建筑业

- : 机械工业

- : 其他行业

上海睿雄实业集团是中国专注于冷镦优质钢丝的标杆企业。整个管理团队拥有20年的行业经验。我们与许多汽车行业的一级供应商建立了良好的关系,所有线材均来自品牌钢厂。所有订单都100% 可追踪。

- : 连续平滑

- : 无接缝、重叠、凹坑、划痕和绘图疤痕

- : 无锈

- : 汽车工业

- : 建筑业

- : 机械工业

- : 其他行业

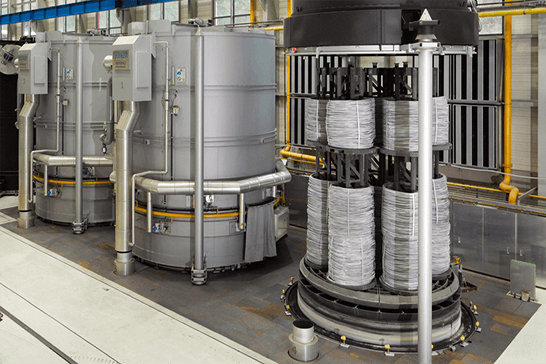

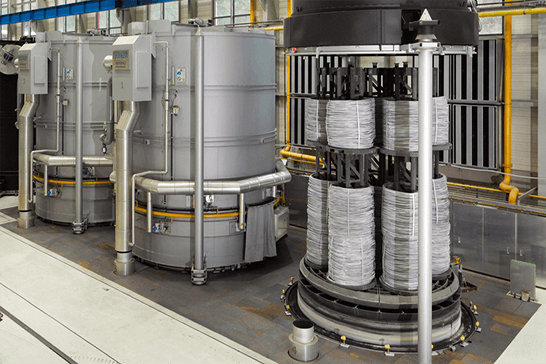

| Delivery condition | Symbols | Product form a | Applicable requirements | |||||

| Wire rod | Bar | Wire | ||||||

| Untreated (as hot-rolled) | +AR | X | X | - | Chemical composition as specified inTable A.2 | Mechanical properties as specified inTable A.3 | Supplementa- ry or special requirements as specified in Annex Eb | |

| peeled Untreatd+ | peeled | +AR+PE | X | X | - | |||

| Cold drawn | +AR+C | - | X | X | ||||

| Cold drawn+ spheroidized | +AR+C+AC | - | X | X | ||||

| Cold drawn+ Spheroidized+skin passed | +AR+C+AC+LC | - | X | X | ||||

| Annealed to achieve spheroidized carbides + | As treated or peeled | +AC or AC+PE | X | X | - | |||

| cold drawn | +AC+C | - | X | X | ||||

| Other | Other delivery conditions may be agreed at the time of ordering | |||||||

| a X=applicable,—=not applicable b Ifagreed at the time of enquiry and order. | ||||||||

| Steel name | %mass fraction a | ||||||||||

| C | Si | Mn | P | S | Cr | Ni | Mo | Al b | Cu | Cr+Ni+Mo | |

| Non-alloy steel grades | |||||||||||

| C2C | 0,03 | 0,10 | 0,20 to 0,40d | 0,020 | 0,025 | 0,30 | 0,30 | 0,10 | 0,020 to 0,060 | 0,30 | 0,50 |

| C4C | 0,02 to 0,06 | 0,10 | 0,25 to 0,40 | 0,020 | 0,025 | 0,30 | 0,30 | 0,10 | 0,020 to 0,060 | 0,30 | 0,50 |

| C8C | 0,06 to 0,10 | 0,10 | 0,25 to 0,45 | 0,020 | 0,025 | 0,30 | 0,30 | 0,10 | 0,020 to 0,060 | 0,30 | 0,50 |

| C10C | 0,08 to 0,12 | 0,10 | 0,30 to 0,50 | 0,025 | 0,025 | 0,30 | 0,30 | 0,10 | 0,020 to 0,060 | 0,30 | 0,50 |

| C10GC | 0,08 to 0,12 | 0,15 to 0,25c | 0,30 to 0,50 | 0,025 | 0,025 | 0,30 | 0,30 | 0,10 | 0,30 | 0,50 | |

| C15C | 0,13 to 0,17 | 0,10 | 0,35 to 0,60 | 0,025 | 0,025 | 0,30 | 0,30 | 0,10 | 0,020 to 0,060 | 0,30 | 0,50 |

| C15GC | 0,13 to 0,17 | 0,15 to 0,25c | 0,35 to 0,60 | 0,025 | 0,025 | 0,30 | 0,30 | 0,10 | c | 0,30 | 0,50 |

| C17C | 0,15 to 0,19 | 0,10 | 0,65 to 0,85 | 0,025 | 0,025 | 0,30 | 0,30 | 0,10 | 0,020 to 0,060 | 0,30 | 0,50 |

| C17GC | 0,15 to 0,19 | 0,15 to 0,25c | 0,65 to 0,85 | 0,025 | 0,025 | 0,30 | 0,30 | 0,10 | 0,30 | 0,50 | |

| C20C | 0,18 to 0,22 | 0,10 | 0,70 to 0,90d | 0,025 | 0,025 | 0,30 | 0,30 | 0,10 | 0,020 to 0,060 | 0,30 | 0,50 |

| C20GC | 0,18 to 0,22 | 0,15 to 0,25c | 0,70 to 0,90d | 0,025 | 0,025 | 0,30 | 0,30 | 0,10 | c | 0,30 | 0,50 |

| C25C | 0,23 to 0,27 | 0,10 | 0,80 to 1.00d | 0,025 | 0,025 | 0,30 | 0,30 | 0,10 | 0,020 to 0,060 | 0,30 | 0,50 |

| C25GC | 0,23 to 0,27 | 0,15 to 0,25c | 0,80 to 1,00d | 0,025 | 0,025 | 0,30 | 0,30 | 0,10 | — | 0,30 | 0,50 |

| Elements not quoted in this table should not be intentionally added to the steel without the agreement of the purchaser,except those intended for finishing the heat.All reasonable precautions shall be taken in order to prevent the addition of elements from scrap or other material used in the production process.However,residual elements may be present provided that they do not affect the mechanical properties and applicability a Maximum values unless otherwise indicated. b Aluminium may be replaced by another element or elements having a similar effect C Grade C10GC,C15GC,C17GC and C20GC can be delivered in two qualities:a)with an aluminium content of Al max.0,015 %,or b)without aluminium and a silicon content of 0,15 %to 0,25 %for hot dip zinc coating d For grades C2C,C20C,C20GC and C25C,a lower manganese content may be specified with a range of 0,20 %. | |||||||||||

| Steel name | Diameter | Delivery Condition | ||||||||||||

| +AR or +AR+PE | +AC or+AC+PE | +AR+C | +AR+C+AC | +AR+C+AC+LC | +AC+C | |||||||||

| above mm | up to mm | Rm max. MPa | Z a min. % | R max. MPa | Z min. % | Rm max MPa | Zmin % | Rm max MPa | Zmin. % | Rmax MPa | Zmin. % | R max. MPa | Zmin. % | |

| C2C | 2 | 5 | — | — | —— | —— | — | — | 310 | 80 | 350 | 75 | — | —— |

| 5 | 10 | 360 | 75 | 450 | 70 | 300 | 80 | 340 | 75 | |||||

| 10 | 40 | 360 | 75 | 440 | 70 | 300 | 80 | 340 | 75 | |||||

| 40 | 100 | 360 | 75 | 440 | 68 | 300 | 80 | 340 | 75 | |||||

| C4C | 2 | 5 | 320 | 77 | 360 | 73 | ||||||||

| 5 | 10 | 390 | 70 | 330 | 75 | 470 | 66 | 310 | 77 | 350 | 73 | 410 | 70 | |

| 10 | 40 | 390 | 70 | 330 | 75 | 460 | 66 | 300 | 77 | 350 | 73 | 400 | 70 | |

| 40 | 100 | 390 | 70 | 330 | 75 | — | — | — | ||||||

| C8C | 2 | 5 | — | — | — | —— | — | 350 | 72 | 390 | 68 | —— | ||

| 5 | 10 | 410 | 65 | 360 | 70 | 490 | 63 | 340 | 72 | 380 | 68 | 450 | 65 | |

| 10 | 40 | 410 | 65 | 360 | 70 | 480 | 63 | 340 | 72 | 380 | 68 | 440 | 65 | |

| 40 | 100 | 410 | 65 | 360 | 70 | — | — | — | — | —— | ||||

| C10C C10GC | 2 | 5 | 一 | 370 | 72 | 410 | 68 | |||||||

| 5 | 10 | 430 | 60 | 380 | 70 | 520 | 58 | 360 | 72 | 400 | 68 | 470 | 63 | |

| 10 | 40 | 430 | 60 | 380 | 70 | 510 | 58 | 360 | 72 | 400 | 68 | 460 | 63 | |

| 40 | 100 | 430 | 60 | 380 | 70 | — | — | — | ||||||

| C15C C15GC | 2 | 5 | —— | — | 390 | 70 | 430 | 66 | ||||||

| 5 | 10 | 460 | 58 | 400 | 68 | 550 | 56 | 380 | 70 | 420 | 66 | 490 | 63 | |

| 10 | 40 | 460 | 58 | 400 | 68 | 540 | 56 | 380 | 70 | 420 | 66 | 480 | 63 | |

| 40 | 100 | 460 | 58 | 400 | 68 | —— | —— | — | — | — | — | —— | —— | |

| C17C C17GC | 2 | 5 | — | — | — | — | — | — | 430 | 67 | 470 | 63 | — | — |

| 5 | 10 | 520 | 58 | 440 | 65 | 610 | 56 | 420 | 67 | 460 | 63 | 530 | 60 | |

| 10 | 40 | 520 | 58 | 440 | 65 | 600 | 56 | 420 | 67 | 460 | 63 | 520 | 60 | |

| 40 | 100 | 520 | 58 | 440 | 65 | — | ||||||||

| a The values are given only for information. | ||||||||||||||