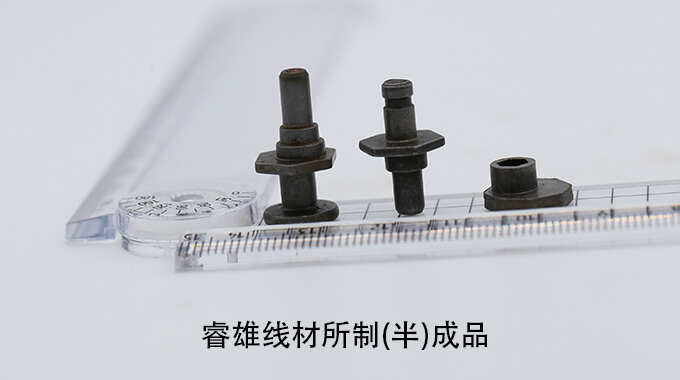

上海睿雄实业集团是中国专注于冷镦优质钢丝的标杆企业。整个管理团队拥有20年的行业经验。我们与许多汽车行业的一级供应商建立了良好的关系,所有线材均来自品牌钢厂。所有订单都100% 可追踪。

交货条件

: AT或AT PE

: 在C

: 在C AT

: 在LC的C处

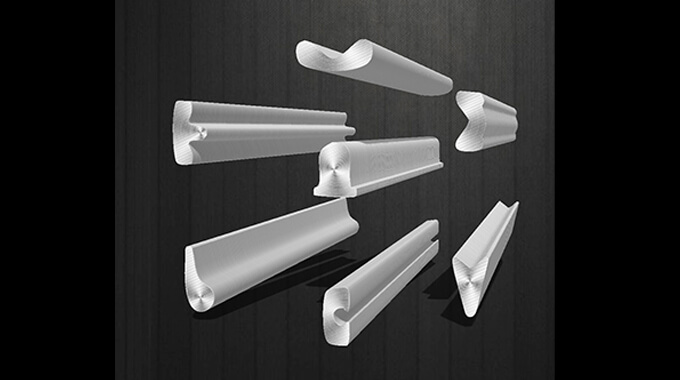

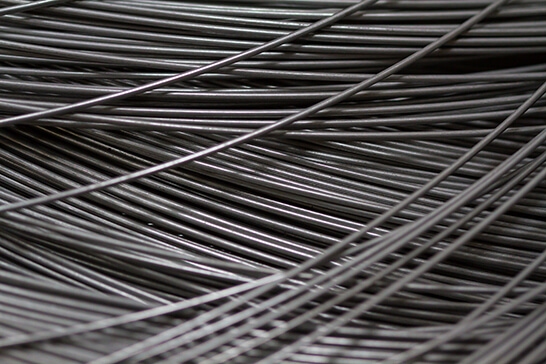

表面质量

- : 连续平滑

- : 无接缝、重叠、凹坑、划痕和绘图疤痕

- : 无锈

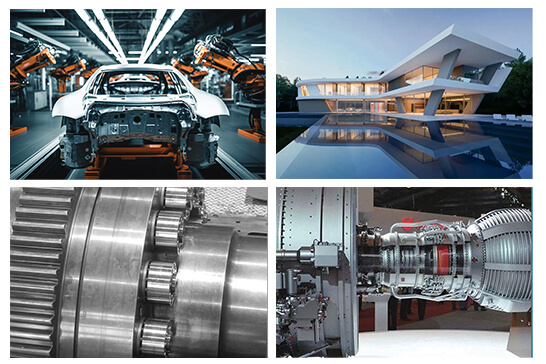

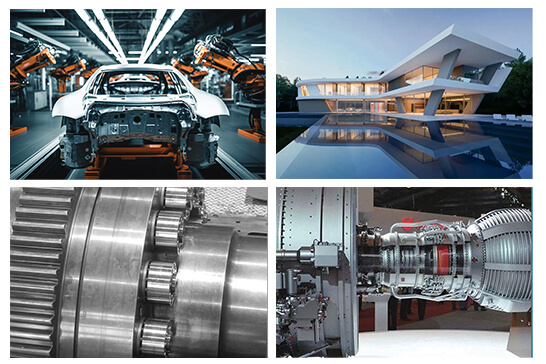

应用程序

- : 汽车工业

- : 建筑业

- : 机械工业

- : 其他行业